[Wroten by ZX VIAL SUPPLIES, CHINA]

Critical Considerations Before You Start

- Pore Size: You must use a 0.22 µm (micron) PES or PVDF filter. This is the sterilizing grade pore size that will remove bacteria and larger microorganisms. A 0.45 µm filter is not sufficient for sterilization.

- Membrane Material: The carrier oil (often cottonseed, grapeseed, or sesame oil) is an organic solvent.

- PTFE (Teflon) or PVDF membranes are chemically compatible with oils and are the standard choice. Avoid Nylon and Cellulose Acetate as they can degrade or swell in oil.

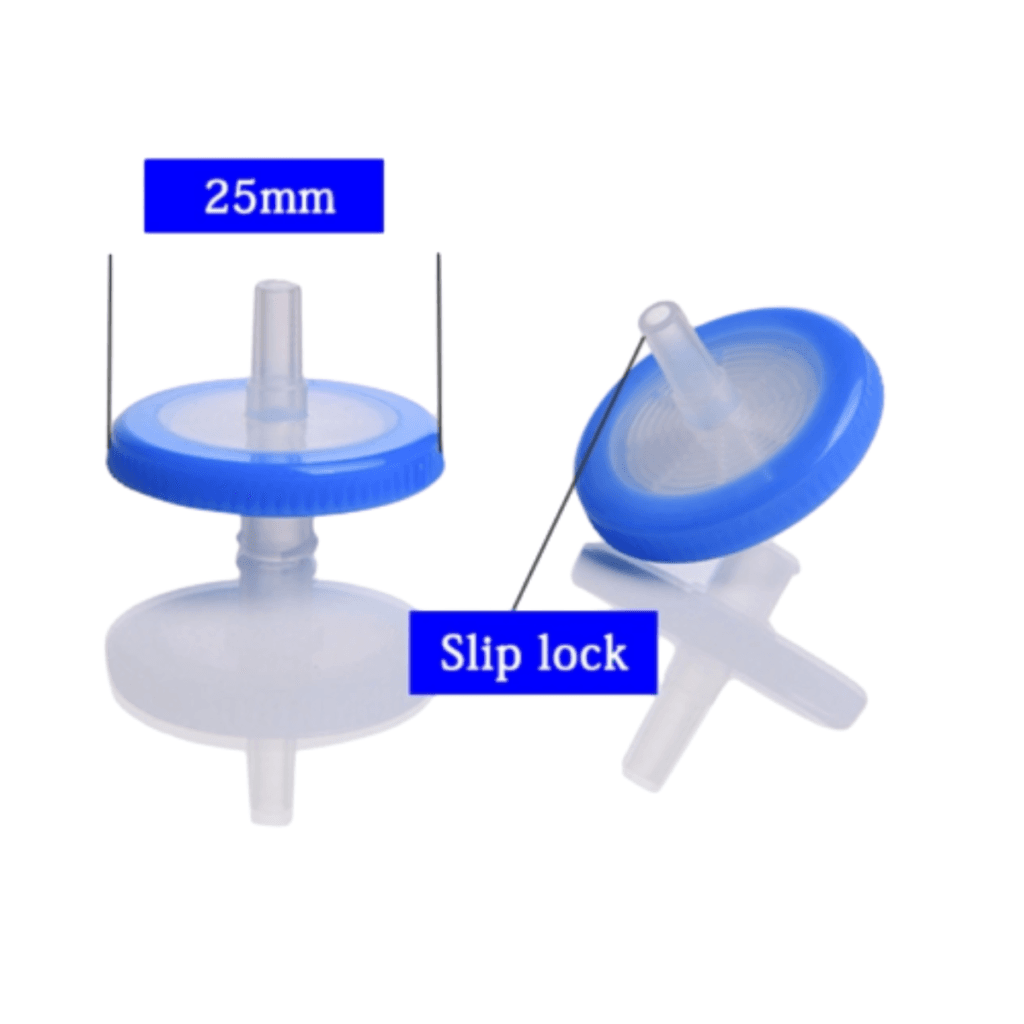

- Size: A 25mm or 33mm diameter filter is recommended. The small 13mm filters will clog almost instantly with thick oil.

- Equipment: You will need:

- Sterile syringe filter (0.22µm, PTFE or PVDF, 25mm+).

- Multiple sterile syringes (e.g., 3mL or 5mL for filtering, larger for final storage).

- Sterile needles (e.g., 18g or 20g for drawing, a fresh sterile needle for injection).

- The raw steroid powder dissolved in carrier oil (the “solution”).

- A sterile glass vial (a “sterile vial”) with a rubber stopper to collect the filtered oil.

- Isopropyl alcohol (70%+) and lint-free wipes.

- Powder-free sterile gloves.

Step-by-Step Aseptic Technique Guide

The goal is to transfer the non-sterile oil solution into the sterile vial without introducing any contaminants.

Preparation: The Clean Field

- Wash your hands thoroughly with antibacterial soap.

- Clean a large, flat surface (like a desk) with isopropyl alcohol. This is your “clean field.”

- Arrange all your sterilized equipment (vials, syringes, needles, filters) on this clean field without touching the critical parts (tips, plungers, needles).

- Put on your sterile gloves. Wipe the gloves with alcohol and let them air dry.

Process: Filtering into the Sterile Vial

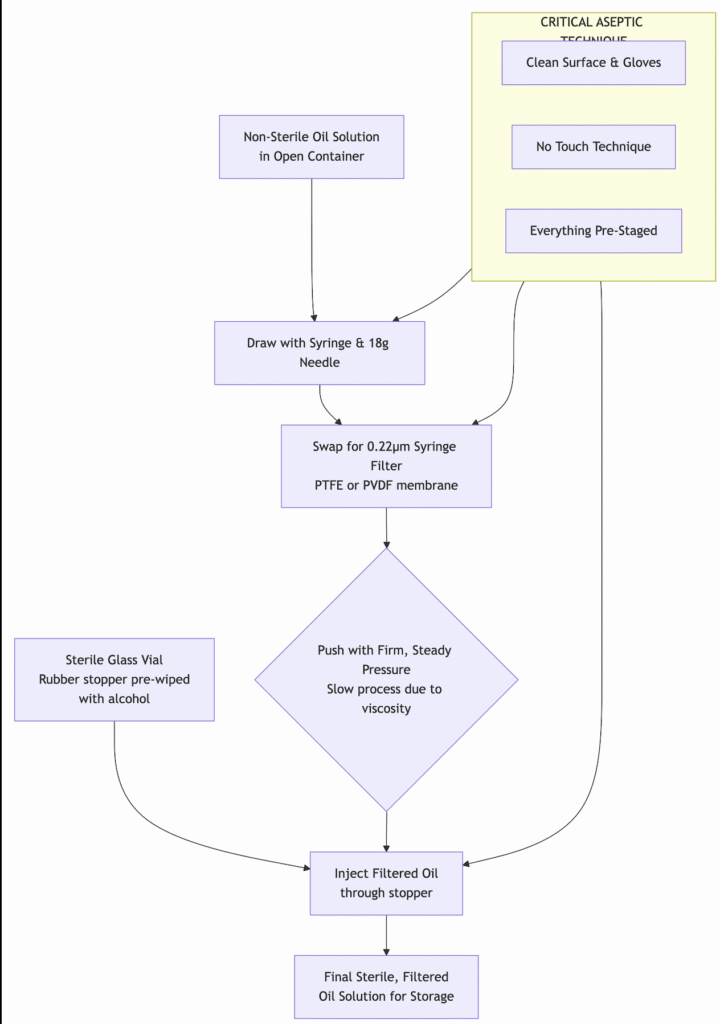

- Draw the Non-Sterile Oil:

- Attach an 18g drawing needle to a syringe.

- Draw the non-sterile oil solution into the syringe. You may want to draw slightly more than your target volume to account for loss in the filter.

- Remove the drawing needle and replace it with the sterile syringe filter. Avoid touching the end of the filter.

- Prepare the Sterile Vial:

- Wipe the rubber stopper of the sterile glass vial thoroughly with an alcohol swab and let it dry completely.

- The Filtration:

- Insert the tip of the syringe filter through the center of the vial’s rubber stopper.

- Apply very firm, steady pressure to the plunger. Filtering oil is very slow and requires significant force due to the viscosity of the oil and the small pore size of the filter.

- Do not force it if it completely stops. If the filter clogs, you will need to start over with a new filter and a new syringe of oil. This is expected and why you have multiple filters.

- Filter all of the oil into the vial.

- Final Storage:

- Once all the oil is in the sterile vial, remove the filter and syringe.

- If you need to fill multiple vials or draw from this master vial later, you must use a fresh sterile syringe and needle each time you puncture the stopper.

Visual Guide to the Setup

The following diagram illustrates the entire setup and process flow:

In summary, while the mechanical process involves drawing oil and forcing it through a 0.22µm filter into a vial, the risks associated with achieving true, safe sterility outside of a controlled lab environment are exceptionally high. The most effective way to ensure a clear and sterile injection is to use a product prepared and tested by a licensed pharmaceutical compounding facility.