[Made by ZX VIAL SUPPLIES.COM. CHINA]

In the world of sealing solutions, butyl rubber and silicone stoppers serve critical yet distinct roles across industries. Butyl rubber stoppers, renowned for their exceptional gas barrier properties, are the go-to choice for pharmaceutical vial closures and airtight laboratory applications. In contrast, silicone rubber stoppers offer unmatched flexibility, biocompatibility, and heat resistance, making them indispensable in medical devices and high-temperature environments. Understanding their differences—from chemical resistance to sterilization compatibility—is key to selecting the optimal material for your specific needs. Let’s delve deeper into how these two elastomers compare and where each excels.

1. Material Composition

- Synthetic elastomer made from isobutylene and isoprene.

- Contains additives for curing and stability.

Silicone Rubber Stopper

- Synthetic polymer made from silicon, oxygen, and organic groups (e.g., polydimethylsiloxane, PDMS).

- Often medical/food-grade with high purity; may include fillers for strength.

2. Key Properties

| Property | Butyl Rubber | Silicone Rubber |

|---|---|---|

| Gas Permeability | Very low (excellent gas barrier, ideal for sealing vials). | Higher (allows some gas diffusion). |

| Chemical Resistance | Resists acids, alkalis, and polar solvents. Poor against hydrocarbons/oils. | Broad resistance but swells in oils/fuels. Better for alcohols and oxidizers. |

| Temperature Range | −50°C to +120°C (short-term up to 150°C). | −60°C to +230°C (some grades up to 300°C). |

| Flexibility | Stiff at room temperature; requires compression for sealing. | Highly flexible even at low temps. |

| Biocompatibility | Good (used in pharmaceuticals but may require coatings). | Excellent (non-toxic, USP Class VI compliant). |

| Aging & UV Resistance | Prone to ozone/UV degradation unless stabilized. | Highly resistant to UV, ozone, and aging. |

| Autoclavability | Limited (degrades with repeated steam sterilization). | Autoclavable (reusable after sterilization). |

3. Applications

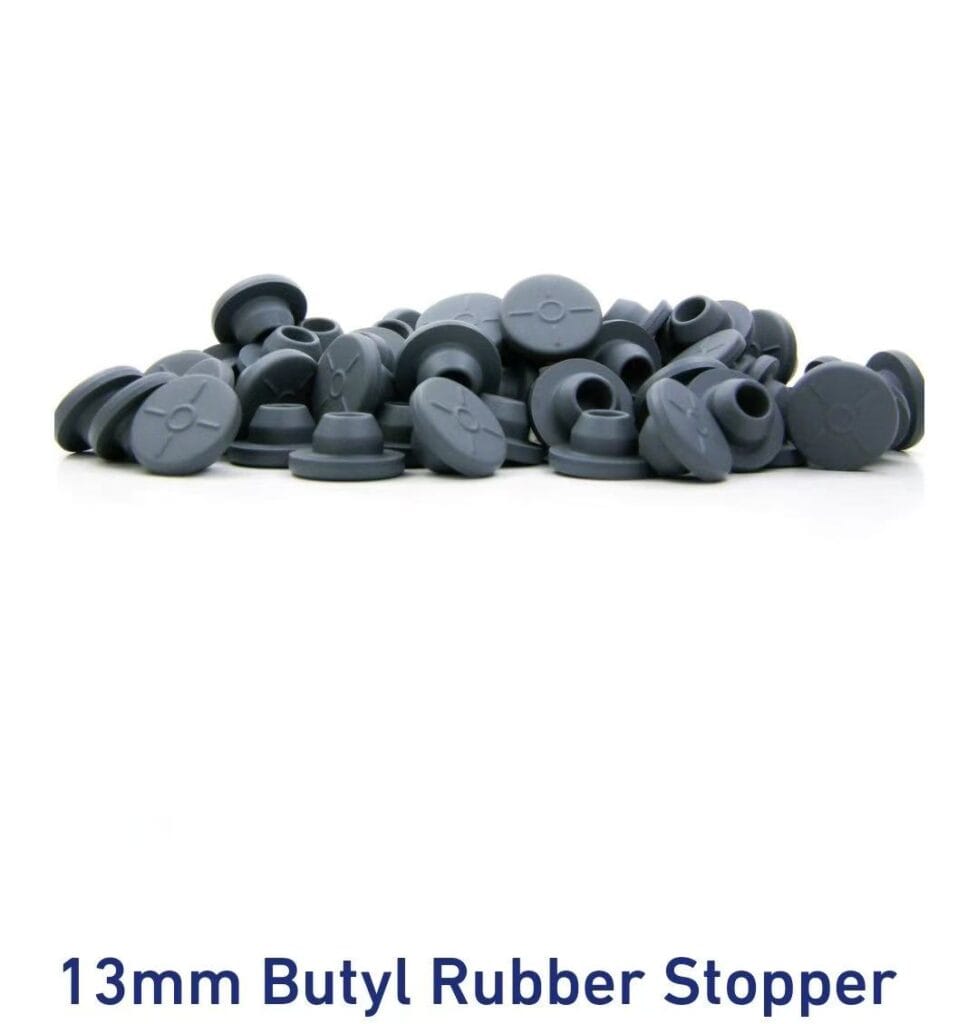

Butyl Rubber Stopper

– Pharmaceutical vial closures (vaccines, injectables).

– Laboratory seals for gas-sensitive experiments.

– Tire inner liners (unrelated to stoppers)

Silicone Rubber Stopper

– Medical devices (syringe plungers, implants).

– Food/beverage seals (breweries, bottling).

– High-temperature lab equipment.

4. Advantages & Disadvantages

| Butyl Rubber Stopper | Silicone Rubber Stopper |

| Pros: – Superior gas/moisture barrier. – Cost-effective for mass production. – Good chemical resistance (non-oily media) | Pros: – Extreme temperature stability. – Biocompatible and non-leaching. – Flexible and easy to sterilize. |

| Cons: – Less flexible; may require lubrication. – Not ideal for repeated autoclaving | Cons: – Expensive. – Poor resistance to oils/strong acids. – Higher gas permeability |

5. HOW to Choose

- Pick Butyl Rubber: You need an airtight seal for pharmaceuticals (e.g., steroid injection 10ml vials; 3ml peptide sterile vials with seals);

- Pick Silicone Rubber : You require biocompatibility, high-temperature use, or flexibility (e.g., medical tubing, autoclave-friendly lab stoppers).

Summary and Suggestions

Butyl rubber used more on pharmaceutical sealing with glass vials, mostly suitable for bodybuilders with steroids oil injections and peptide dry-frozen powder, while silicone rubber is preferred for medical-grade, high-heat, and flexible applications. The choice depends on your specific needs for chemical exposure, sterilization, and environmental conditions.

Both we have, and if you need, you can visit our online shop: https:www.zxvialsupplies.com

DEE

13th Aug, 2025